INTRODUCTION

This article will help guide the end user in a couple approaches

ADDITIONAL RESOURCES

| EXTERNAL DOCUMENT RESOURCES |

| DX100 INFORM Language Instructions |

| DX200 INFORM Language Instructions |

| YRC1000 INFORM Language Instructions |

| YRC1000micro INFORM Language Instructions |

| KNOWLEDGEBASE ARTICLES |

| Maximizing Your Robot's Potential with Relative Job |

TAUGHT POINT METHOD

The taught point method is fairly self explanatory. It involves the user creating a program where each and every point is manually programmed. As with anything, there are advantages and disadvantages to this method that must be considered and applied to your particular situation.

| ADVANTAGES | DISADVANTAGES |

|

|

When should you use the taught point method? I tend to find this method is ideal in situations where the end customer may be newer to automation or when there are only a handful of palletizing patterns. If you are in a situation where you have a medium to large amount of product to palletize (ie: > 7) , this method may not be best as it is more time consuming to develop (yet easier to maintain).

PROGRAMMING STRATEGIES FOR TAUGHT POINT METHOD

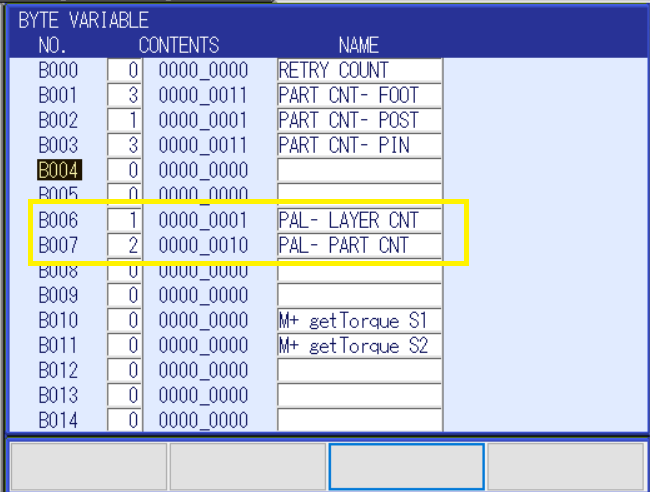

A program using the taught point method typically uses a few robot variables to keep track of the current box number being palletized. Think of them like "pointers". Often you will find 2 variables in use. One for the current layer and one for the current box.

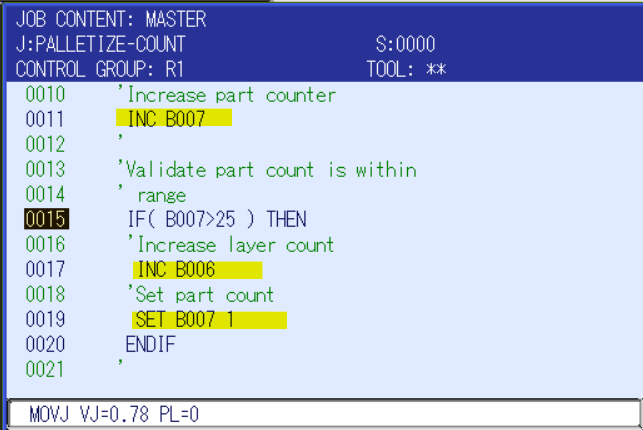

In the example below, we are using byte variable #6 and #7 to keep track of the counts. After each cycle, we are incrementing these counts and also validating that they are within the acceptable range. For instance, if the pallet holds 5 parts per layer and we just placed the 5th part, we would increase our layer count and reset the part count back to 1. The exact method you use to keep track of your placement location will vary and is entirely up to you and your application.

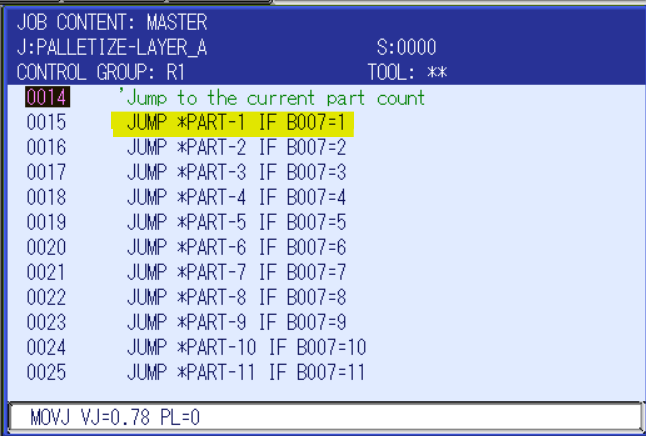

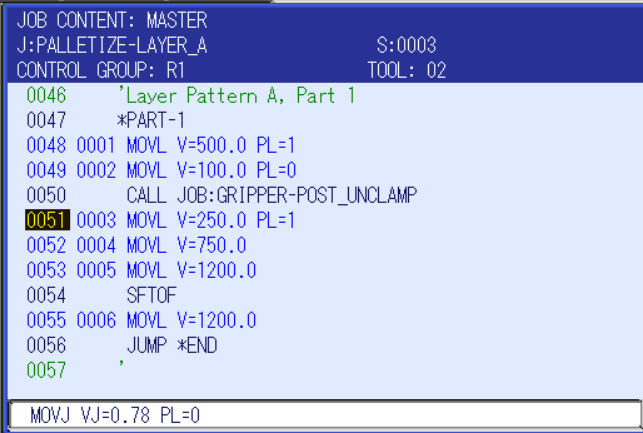

Once you have identified the variables being used to keep track of your part location, the program developed will often have a JUMP command or IF command to ensure the correct points for each box is played back.

With this, you should be able to see the amount of physical points that are required. Plain and simple this just takes time to develop and is why the taught point method may not be best if you need to develop multiple pallet patterns across multiple product shapes and sizes. However... this method is one of the simplest methods to maintain!

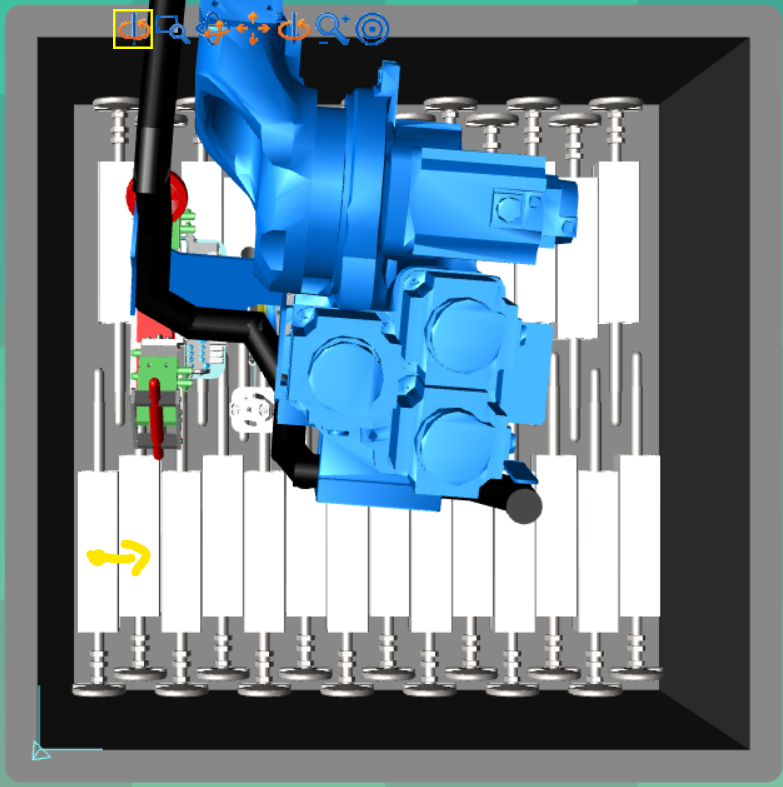

MATH BASED METHOD

A math based approach involves just that.... math! This approach helps minimize the amount of points that must be physically programmed and will use other strategies such as shifting to place the remaining parts on the pallet.

| ADVANTAGES | DISADVANTAGES |

|

|

When should you use a math based approach? Based on the above advantages and disadvantages, it is recommended that you weight the amount of programs required with the end user experience level. If product count is high and end user knowledge level is high then a math based approach may be just what is needed! Regardless... if this method is chosen, we always recommend that you use lots of comments within your code so that someone else can pick-up the pendant later on and easily make any necessary corrections.

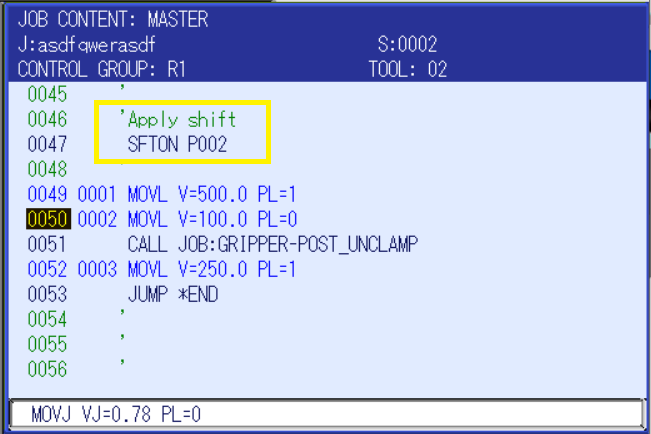

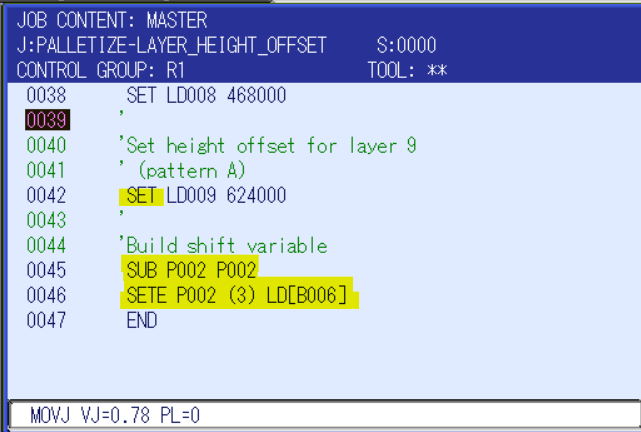

PROGRAMMING STRATEGIES FOR A MATH BASED METHOD

Once again, there are always more then one way to approach a programming challenge. The below guideline is just a suggestion and your experience / comfort level may prefer a different approach.

|

|

|

|

|

|

With a math based approach, you should be able to understand that your program may appear a bit more complex to a novice user. If you do choose a math based approach, please pay attention to your commenting to make it as user friendly as possible!

PALLET SOLVER

Very briefly, we will mention our PalletSolver pattern generation tool. This tool is a special order software function in which the end-user can "draw" a pallet pattern of their choice and the corresponding PC program will generate the entire robot program automatically.

PalletSolver is extremely powerful and has it's advantages in very high mix environments where product size and pallet pattern demands are quite high. There are other articles within our knowledgebase that specifically talk about PalletSolver... The idea here is mainly for you to be aware of it's existence as the purpose of this article is for those developing robot programs from scratch!

Comments

0 comments

Please sign in to leave a comment.