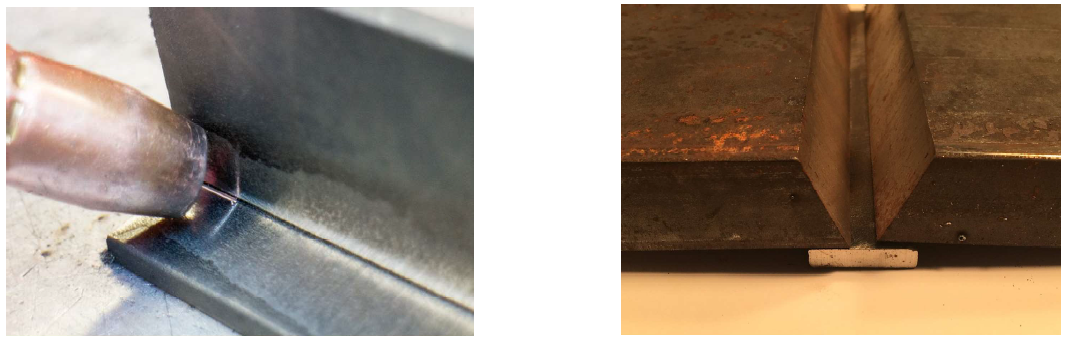

ComArc Seam Tracking is a function that uses amperage feedback from the arc to determine the location of the weld joint. The weld joint must be a fillet joint. Groove joints may be tracked if the joint design provides deep grooves and the joint is not completely filled. ComArc Seam Tracking requires that the Electrical Stick Out (ESO) changes as the wire passes from the center of the weld to the toe of the weld. Fully filled groove welds are NOT recommended. Weaving is required for the ComArc to function.

ComArc Connection Verification

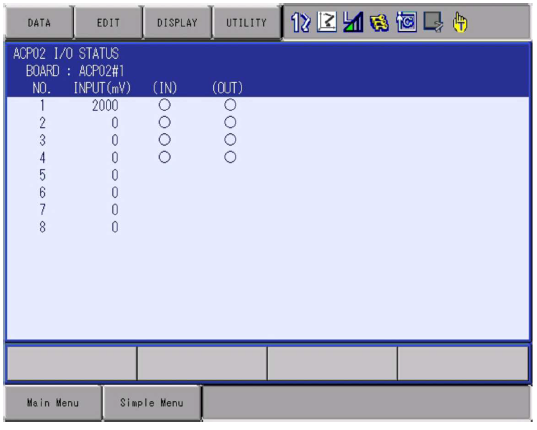

Specific hardware is required to use the ComArc function. This hardware (ACP02 I/O card) processes the amperage, or current, feedback from the power source. This information can be displayed and indicates that the board is functioning properly.

- To view the signals being input to the ACP02 I/O, perform the following:

In PLAY mode, choose In/Out from the Main Menu. - Choose ACP02 I/O.

- Start the weld job and verify the A/D (analog to digital) data on channel NO. 01 shows positive values. If there is no change or if the data is a negative

value, there is a misconnection.

Setting up for ComArc Seam Tracking

The path programmed is performed with the part in the nominal position. Proper Electrical Stick Out (ESO) is essential while programming.

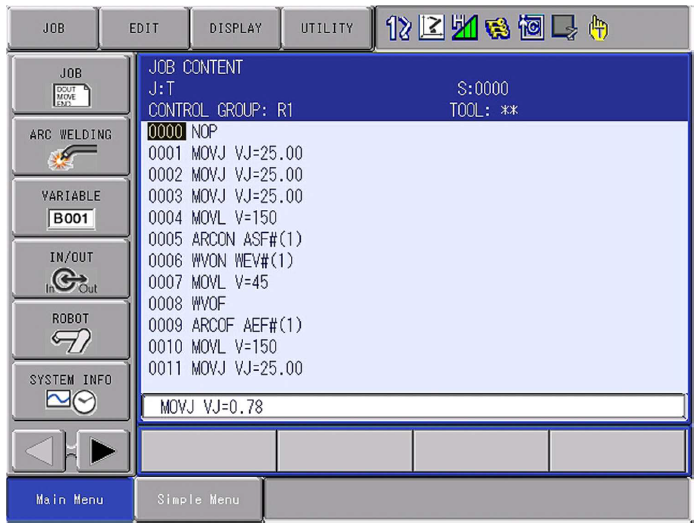

The Job will have an ARCON ASF#(X) and ARCOF AEF#(X) (or any other technique for weld programming) in the proper locations. Weave instructions (WVON and WVOF) must be programmed in this initial job. Test and PLAY the job to ensure good arc characteristics and a proper weld bead with no undercut is deposited.

*To achieve proper results, the length of the test weld should be at least 8 inches. The amplitude of the weave should be at least 2.5 mm.*

Registering the ComArc Instructions

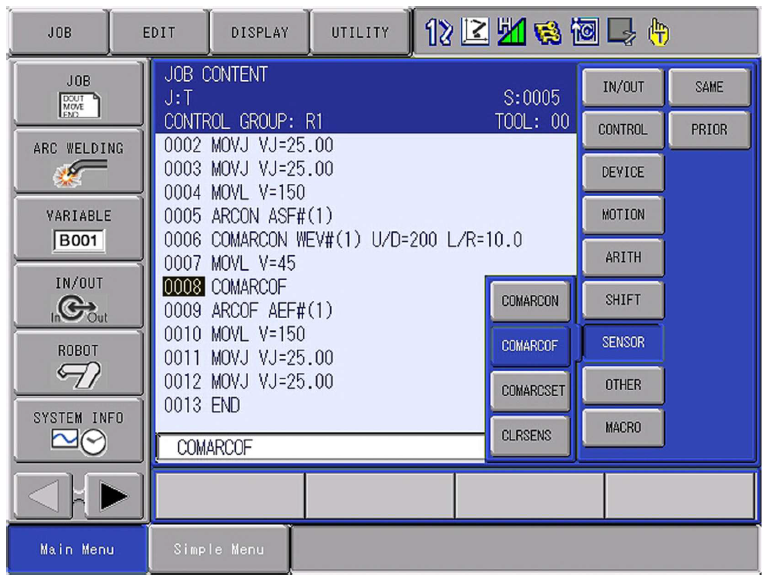

The COMARCON instruction will take the place of the WVON instruction. The COMARCOF instruction will take the place of the WVOF instruction. The ComArc instructions are in the INFORM LIST under the SENSOR selection.

There will only be tracking between the COMARCON and COMARCOF instructions. Any welding outside the COMARCON/COMARCOF instructions will not be

using the seam tracking function.

Measurement and Registration of Information

Two tests must be performed when setting up a ComArc weld. The first is a Phase Compensation test. The second is a Sensing Test. To place the controller in the Measurement Mode, perform the keystrokes below.

- Select the job for measurement.

- Switch into PLAY mode.

- Choose UTILITY through the top menu area.

- Set COMARC MEASURE MODE to valid.

Measurement & Registration of Phase Compensation

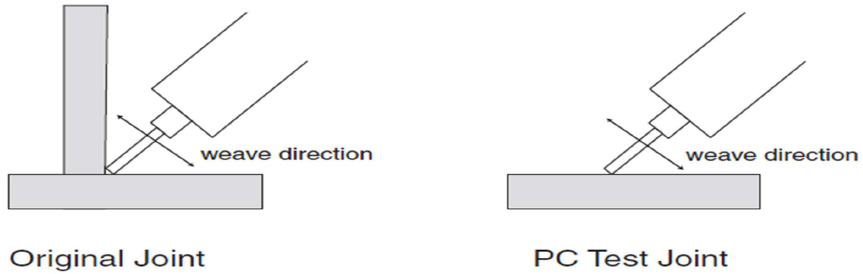

This test will be made with the weld in the same location as the original but without the “top” plate. Follow the steps below.

- Change the security mode to “MANAGEMENT MODE”. Measuring and registering the phase compensation value is only possible in “MANAGEMENT MODE”.

- The phase compensation value is registered in the parameter SxE. To measure and register phase compensation value, set the parameter SxE197 to “1”

- Set measurement mode to valid. (Refer to page 5 for the setting of measurement mode.)

- Execute the job.

- After the Job has been executed, place into Teach mode.

- Select [UTILITY] in top menu

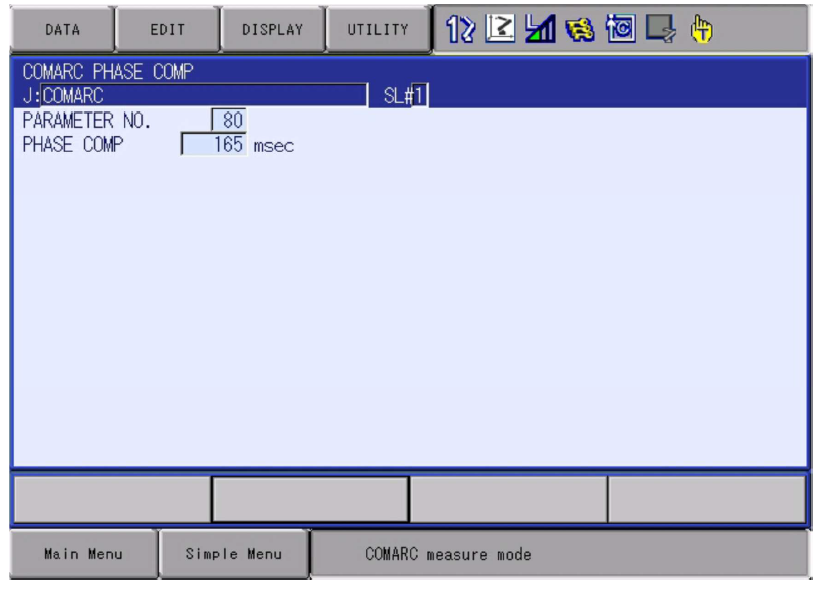

- Select [COMARC COND. MODIFY] *The COMARC PHASE COMP window appears*

- Register the Phase Comp data in the appropriate parameter number.

*Parameter to be changed S1E80=165*

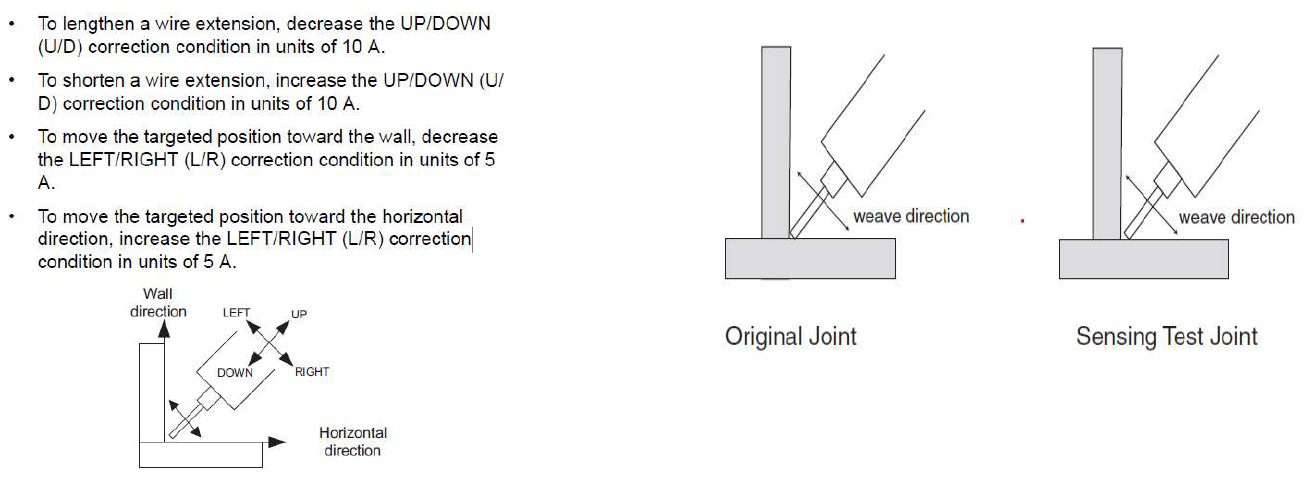

Measurement & Registration of Sensing Conditions

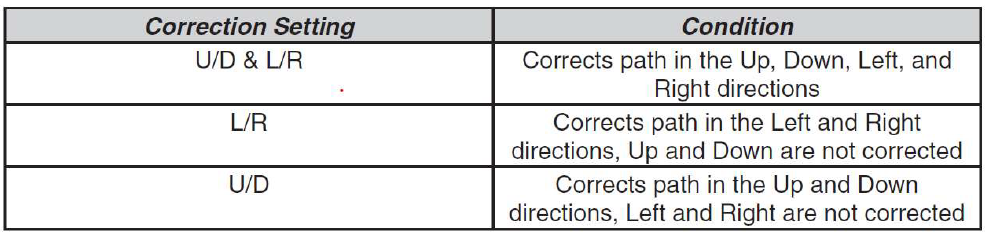

This test will be made with the weld in the same location as the original weld. Below is the relation between the settings of the correction conditions and the

correction direction.

- Measuring and registering the sensing condition values is only possible in “MANAGEMENT MODE”. Change the security mode to “MANAGEMENT MODE”.

- To perform the sensing condition test set the parameter SxE197 to “0”

- Set measurement mode to valid refer to page 5 for the setting of measurement mode.

- Execute the job

- After Job has been executed place into teach mode.

- Select [UTILITY] in top menu

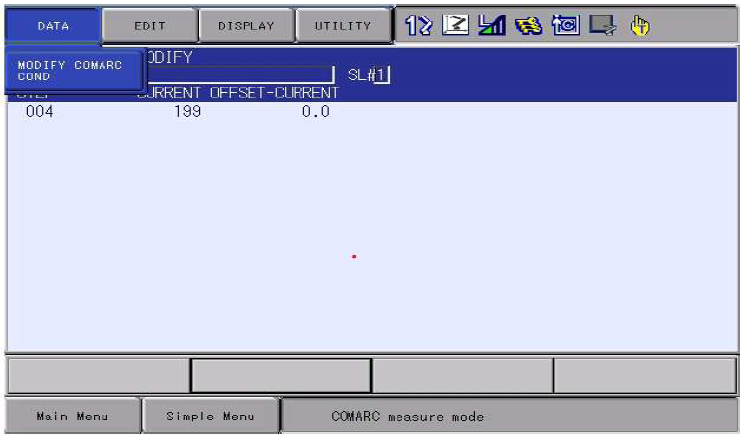

- Select [COMARC COND. MODIFY] *The COMARC COND. MODIFY window appears*

- Select [DATA] in top menu Select "MODIFY COMARC COND" the sensing conditions are now register within the COMARC instruction in the job.

Testing ComArc

**It is important to assure that the COMARC measurement mode is set to INVALID before testing. Refer to page 5 for the setting of measurement mode.**

The test is performed by welding using the COMARCON/COMARCOF instructions with the part in the nominal position. A second weld is made with the part shifted horizontally at the ARCOF end of the weld.

NOTE: By default, the COMARC correction values are between 100 and 150 microns (.100 mm to .150 mm) per weave cycle. If the controller cannot correct enough to follow the joint, the tracking may appear not to work. Changing the parameter for correction amount may allow the controller to properly track the

joint. Incorrect tracking of the offset part may indicate the need to perform the set-up tests again or correction of COMARC parameters.

Slight voltage and weave amplitude adjustments may be made without effecting the tracking. When fillet legs need adjustment, the L/R value on the COMARCON line may be changed. If longer or shorter ESO is required, the U/D value may be adjusted.

Comments

0 comments

Please sign in to leave a comment.