This document will help you setup an Arc World positioner to ensure the rotation direction for the Major axis (S1), and minor axes (S2 & S3) rotate in the correct direction when jogging.

The frames for rotation

- Before attaching any models to the frames, the frames for S1, S2 and S3 will have to be moved and attached to the center of each appropriate axis.

- You can find the 6 part series of the Arc World build video here. https://www.youtube.com/watch?v=CqNZCGDuUeg&t=64s

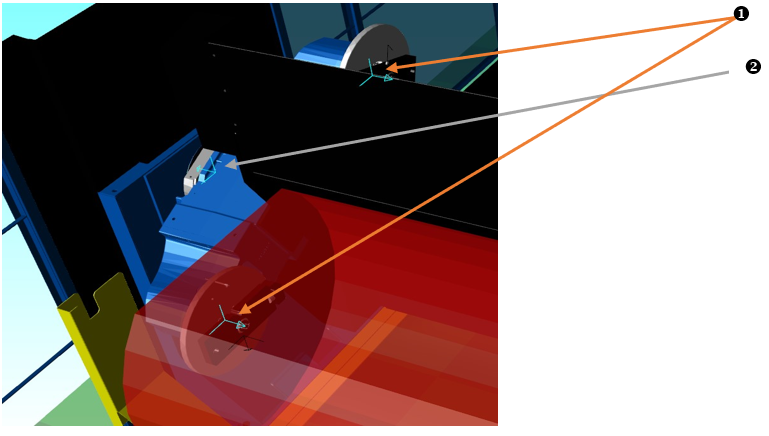

- When attaching the frames, a rule of thumb is: The frame will point away from the motor when direct drive and (1) toward the motor side when indirect drive (2). Like the right-angle gearbox on most of our S1 drives, or main sweep. Pay attention to the flag direction of the frame.

- When you have it all setup and jog the stations, they should move in the direction listed below.

- Station A & B or S2 & S3 should rotate the top of the positioners away from the robot when hitting the plus (+) key.

- Main sweep or S1 should move the top away from the robot if station B(S3) is at the robot to start with, when hitting the minus (-) key. The range for S1 is +5 to -185. The main sweep direction is in the negative direction when sweeping station A to robot. Another way to tell it is correct. Station B (S3) should always sweep over the top of the main sweep. Station A (S2) will always go under.

Conclusion

This will also be how the real positioner should jog. For obvious reasons, there will not be frames to worry about. ALWAYS be careful when programming and sweeping main sweep. Make sure that side A always stays in the flat when sweeping, so that the tooling does not collide with floor. You should always have a job that is S1S2S3 when sweeping, and should look like a Ferris wheel, keeping station A and station B in the flat.

Comments

0 comments

Please sign in to leave a comment.