Introduction

When manipulators have sequences that provide the possibility of crashing into one another arm interference can be used for collision avoidance, when the manipulators are on the same controller. When manipulators are on separate controllers, interference code must be added to ensure that the manipulators do not collide.

In welding scenarios interference code is implemented with handshakes between controllers and T sync commands. (I/O is manipulated in robot jobs). Material handling (and others) may have processes that do not allow this method to be used. There are two scenarios described in this document:

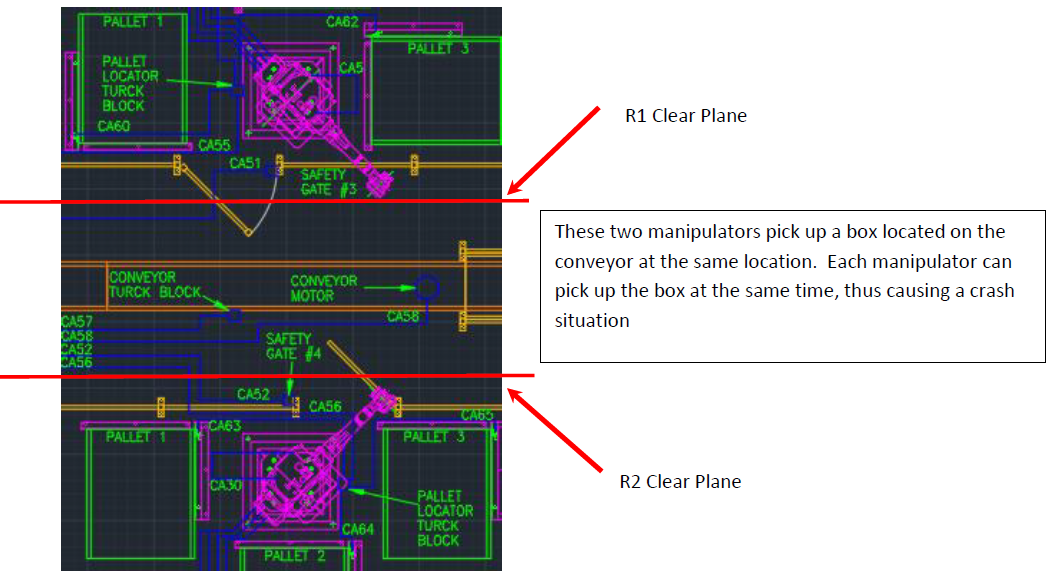

- Scenario 1 – Manipulators from separate controllers are performing parallel operations such as pick or place at the same location and

- Scenario 2 – Manipulators from separate controller are performing sequential operations such placing then welding.

Scenario 1 - Manipulators from separate controllers are performing parallel operations such as pick or place

Sequence for robots entering interference (pick) zone (robot 2 sequence is the same).

Note that other backchecks and sequences occur. The interference sequence is the only one reviewed here.

- Robot 1 requests to enter pick zone from PLC

- Robot 1 verifies input OK to enter pick zone

- Robot 1 moves toward interference zone

- Robot 1 plane for clear of interference zone turns off

- Robot 1 Picks box

- Robot 1 moves clear of interference zone

- Robot 1 plane for clear of interference zone turns on

Note: If a base track is used, and TCP plane and plane cube may need to be used for clear.

Robot clear planes needs to be defined so to ensure stopping distance when both robots are not clear. The request to enter logic must be added to each robot job that enters the interference zone, including other processes than the standard sequence. For example, QC processes.

PLC Required I/O for each Controller

Inputs

| 1 | Request To enter interference zone |

| 2 | Clear of Interference Zone Plane |

| 3 | Play Mode |

Outputs

| 1 | Ok to Enter Interference Zone |

| 2 | Servo Off Cat0 |

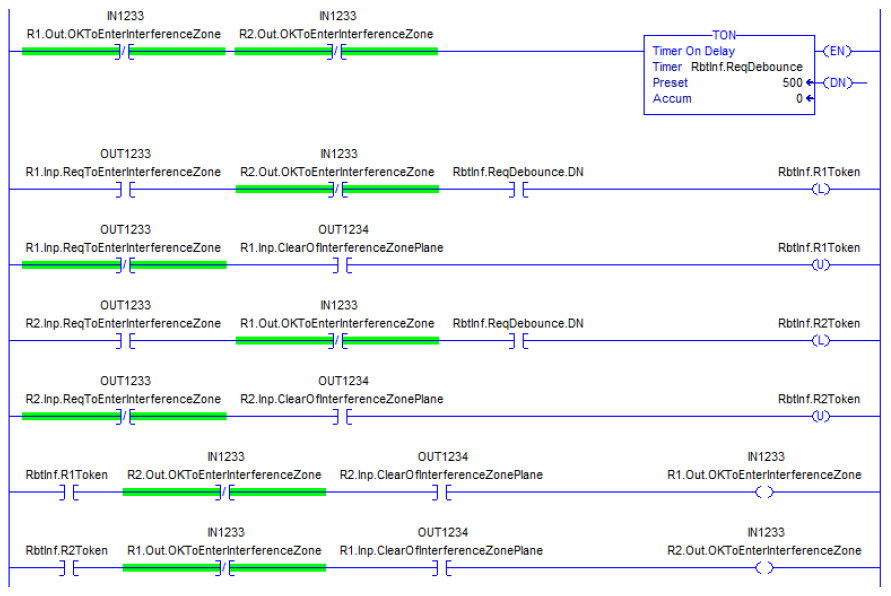

PLC Logic

- Robot 1 or 2 request to enter pick zone

- PLC checks if “token” is already given to a robot

- If token is in PLC, PLC assigns “token” to the robot requesting, thus turning on the OK to enter pick zone input of robot

- Token is returned to PLC when picking robot is clear of the pick zone (plane) and no longer requesting to enter.

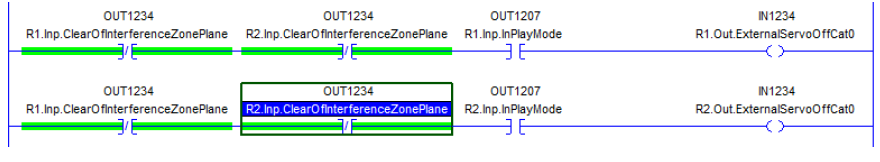

PLC backcheck

If both manipulators are at the pick zone (not clear cubes) at the same time, servo off while in play. Use cat0 servo off.

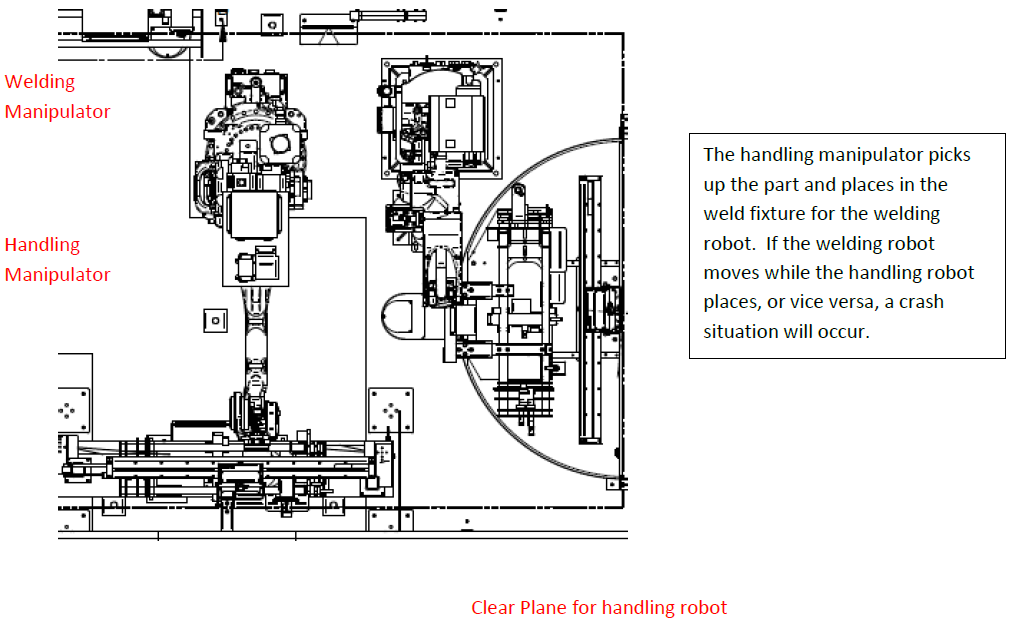

Scenario 2 – Manipulators from separate controller are performing sequential operations such placing then welding.

Sequence for robots

- Welding robot is at home

- Handling robot places part and returns clear of the welding robot

- Welding robot welds part

A 25mm home cube must be used for the welding robot

Handling robot clear plane must be used so to ensure stopping distance when the welding robot is not home.

PLC Logic

- Verify welding manipulator at home cube in the handling robot ok to place signal

- Verify the handling robot clear (place) in the ok to weld signal of welding robot

PLC Required I/O for each Controller

Handling Robot

Inputs

| 1 | Clear Plane |

| 2 | Play Mode |

Outputs

| 1 | OK to Place |

| 2 | Servo Off Cat0 |

Welding Robot

Inputs

| 1 | Home Cube |

| 2 | Play Mode |

Outputs

| 1 | OK to Weld |

| 2 | Servo Off Cat0 |

PLC backcheck

If the handling robot is not clear and the welding robot is not home, servo off while in play for the handling and the welding robot. Use cat0 servo off.

Comments

0 comments

Please sign in to leave a comment.